Patent-Pending Innovation

The Engineering Breakthrough That Makes 30-Day Installation Possible

Our revolutionary Slip-Lock® connectors and anchor pin system transform how barriers connect and secure, delivering permanent-grade protection with modular flexibility. See why cities are abandoning complex installations for our simple, secure solution.

ASTM A572 Grade 50 Steel

ASTM A449 Grade 50 Pins

No Special Tools Required

Creates a Continuous Steel System

Product Overview

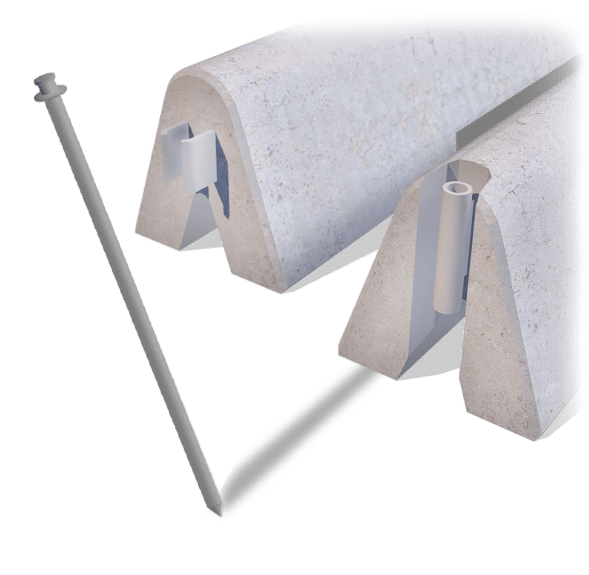

Slip-Lock® Connector and Anchor Pin

This isn't just hardware—it's the innovation that solved the industry's biggest challenge: how to create unbreakable connections without permanent installation. Our patent-pending Slip-Lock® connectors unite barrier sections with precision-machined steel components, while our engineered anchor pins provide stability without excavation. Together, they deliver the strength of welded connections with the flexibility of modular design.

What once required weeks of concrete work, specialized crews, and road closures now happens in minutes with standard equipment. Each connection maintains our continuous steel system while allowing future adjustments whenever your city's needs evolve. This system represents a fundamental shift in how protective infrastructure gets installed, maintained, and adapted.

Key Benefits

Why This Changes Everything for Infrastructure Projects

Unbreakable Safety Without Compromise

Creates One Continuous Line of protection

No weak points between sections

Maintains certification across entire installation

Installation Speed That Defies Logic

Connect Barriers in under 60 seconds per joint

No Drilling, Welding, or Concrete Work

Hundreds of Feet installed daily with a standard crew

Immediate load-bearing capacity

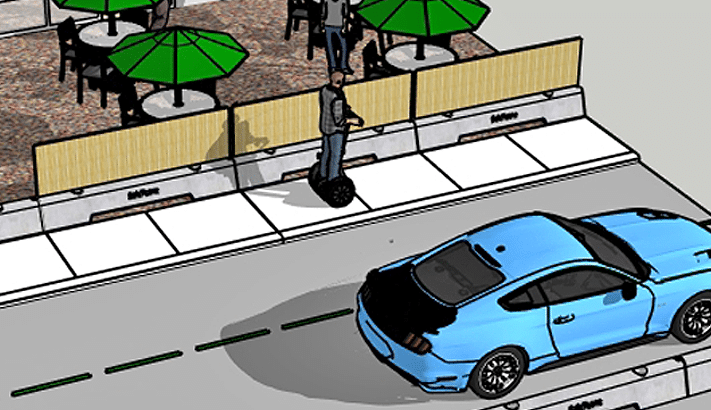

Flexibility Cities Have Never Had

Unlock and Reconfigure for special events

Adjust Layouts as traffic patterns change

Remove Sections for utility work

Expand Networks without starting over

Engineering Precision Meets Practical Design

Self-Aligning Channels eliminate guesswork

Corrosion-Resistant Materials ensure longevity

Universal Fit with all SAFE-T Lane® Dividers

Proven in extreme weather conditions

Technical Specs

Precision Engineering in Every Component

Slip-Lock® Connector Specifications

Material – ASTM A572 Grade 50 Steel

Patent-Pending – Male and Female Connectors

Engineered – For optimal strength

Load Rating – Exceeds barrier capacity

Installation Time – <60 seconds

Anchor Pin

Specifications

Material – ASTM A449 Grade 50 Steel

Length Options – Variable by surface

Installation – Vertical drive method

Surface Compatibility – Asphalt/Concrete

Pullout Resistance – Certified ratings

Corrosion Protection – Available

Download Full Engineering Specs

View CAD Drawings

Watch Crash Test Video

Applications

Securing Protection Across Every Surface

Asphalt Surfaces

Direct drive installation through standard asphalt depths with no pre-drilling required.

Concrete Pavements

Specialized installation methods for existing concrete with minimal surface disruption.

Composite Surfaces

Adaptable anchoring for complex road compositions and overlay situations.

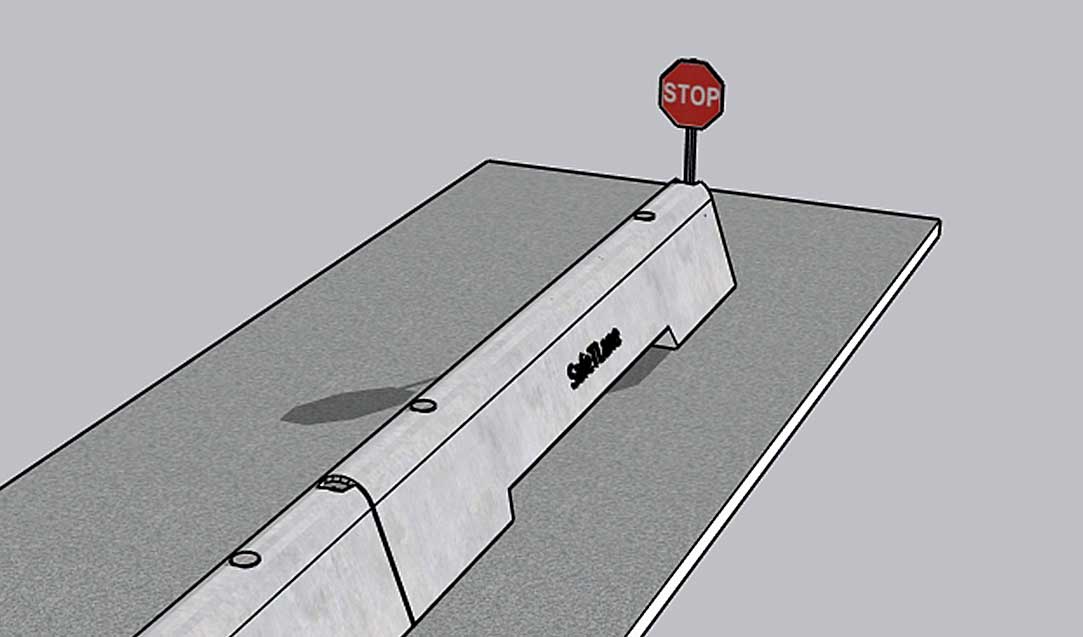

Temporary Installations

Reduced anchoring for event management and pilot programs.

Bridge Decks

Alternative securing methods that protect structural integrity.

Utility Corridors

Flexible positioning to avoid underground infrastructure.

interested in making your space safeR?

Contact us to discuss your project needs and find the best solution

Get a quote todayInstallation Simplicity

Complex Engineering Made Remarkably Simple

Four simple steps

1. Align Barrier Sections

Position barriers end-to-end

Self-locating channels guide alignment

No measuring or manual adjustment

2. Insert Slip-Lock® Connector

Slide barrier vertically through channels to complete the connection

Gravity does the work

Instant mechanical lock achieved

3. Drive Anchor Pins

Drill anchor pin holes in roadway surface

Drive pins through the Male Slip-Lock® Connector with standard equipment

4. Verify and Go

Visual confirmation of connection

No curing or waiting time

Full strength immediately

Quality & Durability

Built to Outlast the Barriers They Connect

Quality Assurance Points

Patent Pending

Design uses ½” plate steel and 2” diameter steel pipe

Fatigue Testing

Proven through millions of load cycles

Temperature Stable

Performs from -40°F to 120°F

Impact Distribution

Spreads forces across barrier system

Maintenance-Free

No adjustment or tightening required

Replacement Ready

Individual components easily serviced

Testing Standards

Exceeds all applicable ASTM and AASHTO requirements

Customization Options

Make It Yours

Visual Enhancements

Custom vinyl wraps with city branding

Advertising space for revenue generation

Artistic designs for cultural districts

Wayfinding integration

Safety Upgrades

Embedded reflectors for night visibility

Solar-powered LED accent lighting

Warning signage mounting points

Textured surfaces for specific applications

Functional Additions

Bike rack mounting capabilities

Banner holder attachments

We replaced 2 miles of flex posts with SAFE-T Lane barriers and saw cyclist complaints drop 85% in the first year. What really sold us was the ability to reconfigure sections for our weekly farmers market—something permanent concrete could never do.

maria rodriguez, Traffic Engineer, City of Boulder

Ordering & Support

Ready to Transform Your Infrastructure?

Get Started

Free project consultation

CAD drawings

Site evaluation available

Pilot program options

Resources

Installation videos

Maintenance guides

Technical support

The SAFE-T Lane® Guarantee

Your Investment Protected

Pilot Program

Test 100 linear feet risk-free

Performance Guarantee

Full credit if unsatisfied

Delivery Promise

On-time or credit applied

Lifetime Support

Free technical assistance forever